Thermoelectric materials can convert heat into electricity, and this has great potential, because over half of all the global energy produced ends up as waste heat. Universities and companies all over the world are therefore researching into developing efficient and inexpensive materials to contribute to the green energy systems of the future.

But it's not easy. The material must have high electrical conductivity, low thermal conductivity and, of course, a chemical composition that enables it to convert heat energy into electrical energy.

And clearly the material must be able to withstand the high temperatures in the environments in which it will be used.

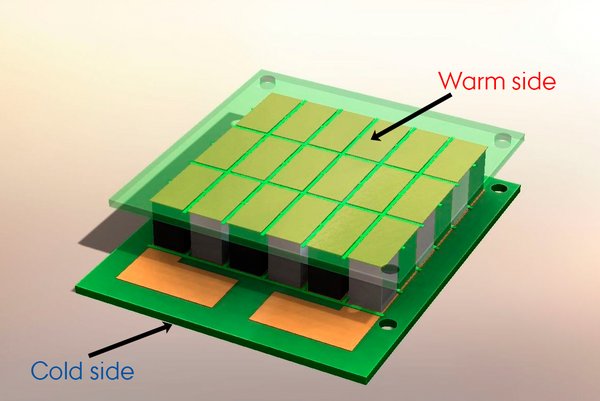

Tolerating high temperatures turned out to be exactly the problem facing an otherwise promising material, zinc antimonide (Zn4Sb3), which in 2012 became the basis for the company TEGnology ApS in Hedensted, Denmark. The company develops and sells thermoelectric materials and components that can effectively convert heat into electricity. Unfortunately, it turned out that the material broke up at high temperatures.

To find the cause, TEGnology needed to look inside the zinc antimonide while the material was in use at high temperatures.

Among other things, this requires a very powerful X-ray, so TEGnology contacted the social partnership LINX (Linking Industry to Neutrons and X-rays, see "Facts about LINX"), which put the company in contact with the Center for Materials Crystallography at the Department of Chemistry.

The centre has access to the world's most powerful synchrotron-based X-ray sources. However, in order to find out why the material broke up, researchers had to develop a method to mimic the conditions it is exposed to when it is used in industry. In other words, the zinc antimonide samples had to be warmed up to 400-500 degrees centigrade at one end, and kept cold at the other end, while;they were exposed to intense X-ray radiation.

In short, they successfully developed an instrument that could simultaneously

… after which, using two different methods of analysis – powder diffraction and PDF (Pair Distribution Function) – the researchers could look at both the crystalline and amorphous components and get a complete picture of the whole sample.

And what did the image show?

That the electrical potential created by the material during the warming makes zinc ions migrate. This makes the zinc-deficient materials in the sample change, and the sample breaks.

"We haven’t used the tool to observe something that we haven’t been able to explain before. We can look at very small changes, small expansions, and movements of atoms that you can't see otherwise," explains PhD student Lasse Rabøl Jørgensen, who helped develop the instrument.

The tool can be used for anything related to ion conduction in materials research, for example to analyse ferro electrical materials, piezo electrical materials and electrolytes in batteries.

The study of zinc antimonide resulted in an article in the scientific journal IUCrJ.

Since then, the research group has examined other samples from TEGnology in connection development of new systems by the company.

The head of technology at TEGnology and co-owner, Hao Yin, is enthusiastic about the collaboration.

"This has meant everything for our future. Only one thing can secure development for a small start-up company like TEGnology: namely the technology. When we talk to customers, investors and partners, the collaboration means that we have access to state-of-the-art research, development and results. We’re a hi-tech company, based on a patent that is now ten years old, and when new technology becomes old technology, we need to keep up with high-speed research and development. We get this at Aarhus University through LINX," says Hao Yin.