Danish Plastics Federation awards prize to research group from Aarhus University for the second consecutive year

The research collaboration RePURpose is behind a new technology to recycle polyurethane, and it has been awarded the Plastics Prize 2024. Last year, the prize went to a research project on recycling wind turbine blades. The awards are evidence of the university's strong position within research into green solutions, says the award winners from the Interdisciplinary Nanoscience Centre at Aarhus University.

There is strong demand for smart technology to recycle materials in industry. However, not all plastic can be easily disassembled into small building blocks for reuse in new products. This applies for polyurethane (PUR), for example, which is used to manufacture insulation for refrigerators, and in sports clothing, shoes, mattresses, wind turbine blades and cars. As a result, end-of-life products containing PUR often end up in landfills or incinerators.

However, a research collaboration with Professor Troels Skrydstrup and Assistant Professor Steffan Kvist Kristensen from Aarhus University has cracked the code for how to extract the smallest fractions from polyurethane: polyols and diamines. If separated, these fractions can be used in the manufacture of new refrigerators, clothes or mattresses.

The technology behind the process has just been awarded the Danish Plastics Federation's prize. The prize is awarded for extraordinary and commendable achievements in the Danish plastics industry.

"We're very proud and happy to receive the 2024 Plastics Prize. The world is calling for green solutions, and this award is the industry’s way of saying that our method is a step in the right direction," says Troels Skrydstrup, who heads the RePURpose collaboration at the Interdisciplinary Nanoscience Centre and Department of Chemistry at AU.

In the nomination of RePURpose, the jury emphasised that the project has paved the way for a circular economy for PUR plastic. The material accounts for approx. eight per cent of global plastic production, but it does not lend itself to recycling in the same way as more common plastic types used for packaging, for example. Therefore, the method can make a big difference, says Troels Skrydstrup.

"Potentially, we're looking into a future where many tonnes of PUR can be recycled and used in new products. This puts Denmark in a strong position in relation to the green agenda, and we're delighted to be contributing to this," says Troels Skrydstrup.

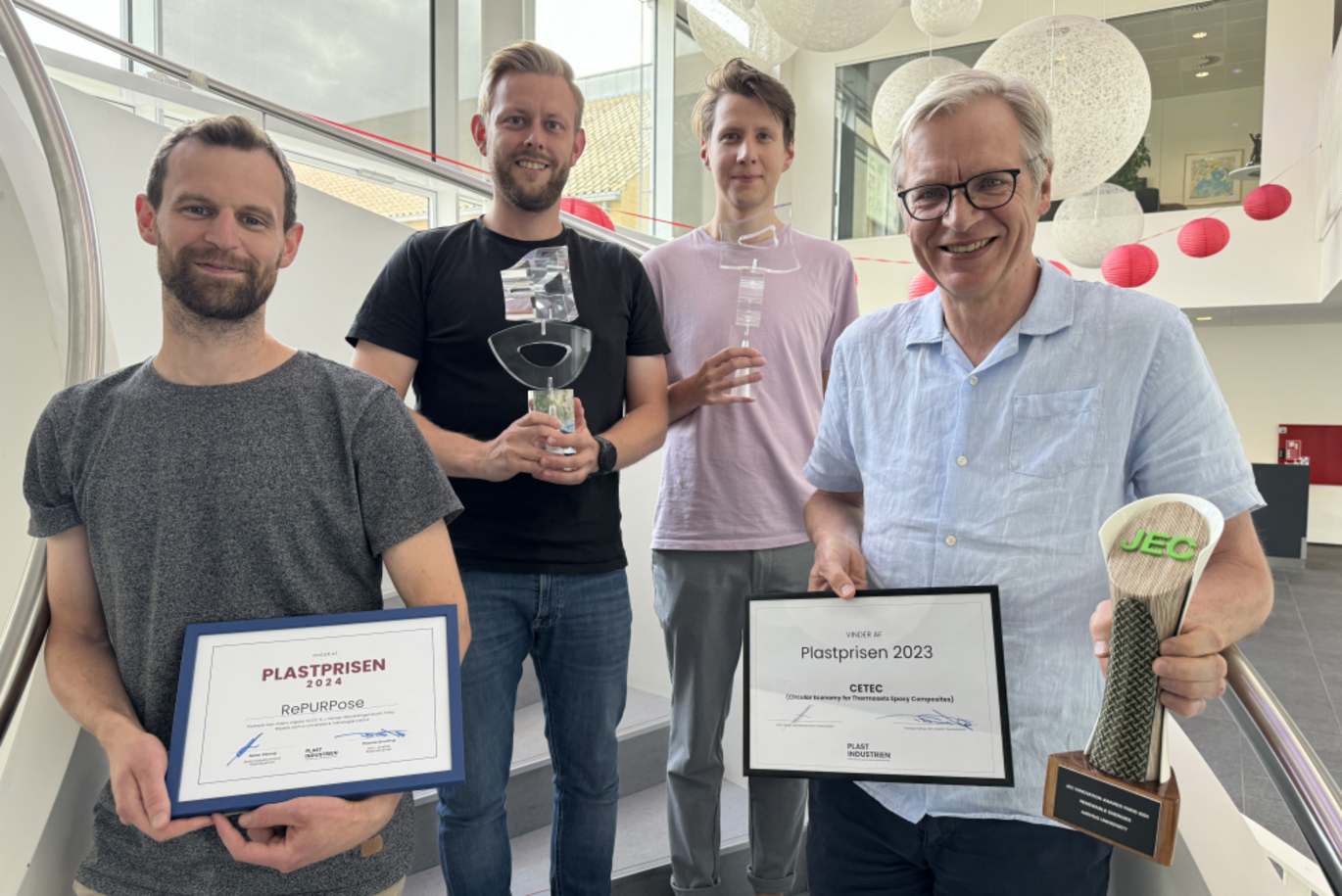

This is the second year in a row that a research partnership with Troels Skrydstrup's research group from the Interdisciplinary Nanoscience Centre and Department of Chemistry has received the Plastics Prize. In 2023, CETEC, Circular Economy for Thermosets Epoxy Composites, received the prize for developing a method for recycling wind turbine blades. CETEC's method separates the chemical components so that they can be used in the production of new blades. For the wind turbine industry, being able to reuse the material from the giant thermoset fibreglass blades is crucial and it means the blades no longer have to end up in landfills.

"It's a huge recognition to receive the Plastics Prize for the second year in a row for projects aimed at making difficult-to-recycle plastics recyclable. To top it off, we've also been awarded the international 2024 JEC Composites Innovation Award for our work on epoxy recycling. The awards are testament to our strong research environment at Aarhus University, which is geared towards solving major problems of relevance to society," says Troels Skrydstrup. He stresses that collaborating with industry and the Danish Technological Institute (DTI) has been essential in arriving at the award-winning solutions.

"There's still a long way to go before the technology is a commercial success, but we're on the right track."

Besides Aarhus University, the RePURpose project comprises a number of partners: Dan-Foam, Logstor, ECCO, H. J. Hansen Genvindingsindustri, Tinby, Plixxent and the Danish Technological Institute (DTI).

CETEC is a collaboration between Vestas, Aarhus University, Olin and the Danish Technological Institute. Further scale-up endeavours will be in collaboration between Vestas, Olin and Stena Recycling.

Contact:

Troels Skrydstrup, professor

The Interdisciplinary Nanoscience Center (iNANO)

Department of Chemistry

Email: ts@chem.au.dk

Tel.: +45 28 99 21 32

Steffan Kvist Kristensen, assistant professor

The Interdisciplinary Nanoscience Center (iNANO)

Email: skk@inano.au.dk

Tel.: +45 28 15 41 00